Flow control valves

author: MSc. Paweł Stańczyk

Flow control valves are used where it is required to limit or control the speed of movement of the hydraulic actuator. There are several types of flow control valves with different methods of connection, adjustment and precision of operation. Choosing the right valve depends on many factors.

Throttle valves

The simplest type of flow control valves are throttle valves. The valve is adjusted by changing the size of the throttling point. Controlling the flow rate by means of throttling is associated with increasing the flow resistance in the regulated part of the system, which generates power losses. It should be remembered that the flow rate depends on the pressure difference in the parts of the system and the viscosity of the hydraulic fluid, which decreases with increasing temperature.

Throttle valves can be successfully used in hydraulic systems in which there is a constant operating resistance or the change of the flow rate with variable load of actuators does not matter.

2-way flow regulators with pressure drop compensation

Solutions in which the flow is adjusted by changing the size of the throttling point may be found on the market. The compensator is designed to maintain a constant pressure drop across the throttling point. Maintaining a constant pressure drop ensures a constant flow through the set throttling point, regardless of the load of the actuators in the part of the system and of the pressure in the supply. This solution was used in 2FRM valves.

Another solution is to adjust the valve by adjusting the preload of the compensator spring 2. The oil flow rate through nozzle 1 depends on the pressure difference across nozzle 1.

The compensator (poppet 3) is there to maintain a constant pressure drop, set by the spring 2 tension.

The increase in flow will increase the force on the poppet 3 resulting from the pressure drop across the nozzle 1. This will move the poppet 3 of the compensator and increase the throttle on the edges of the poppet until a new equilibrium position is obtained. Maintaining a constant, set pressure drop on the nozzle 1 ensures a constant flow in the system part, independent of the load on the actuator, in accordance with the valve characteristic. It should be bore in mind, that the regulation is obtained by introducing the flow resistance in the regulated system part, which is associated with the power losses of the system.

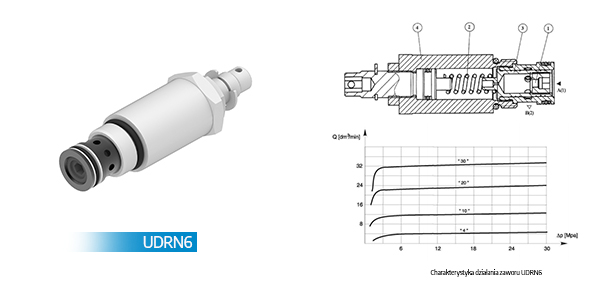

3-way flow regulators with pressure drop compensation

These regulators make it possible to control the speed of movement of the actuator - most often the piston rod of a cylinder or hydraulic motor, regardless of the pressure on the supply (pump) and independently of the resistance on the hydraulic actuator. The principle of the regulator's operation is to divide the supply stream (port 1) into a priority stream directed to port 3 and a residual stream (port 2).

Using the setting 2, adjustment to the throttling point of the spool 1 can be made. A differential valve consisting of a piston 3 and a spring 4 ensures a constant pressure drop across the throttle point. As a result, the flow rate through port 3 will be constant, irrespective of the supply pressure (port 1) and the pressure at the actuator (port 3). It will solely depend on the regulator's setting position.

An additional advantage of the three-way valve is the fact that, once the desired flow in the priority stream has been achieved, the remaining output is released into the residual stream without causing any further pressure increase in the supply port. This results in saving the power consumed by the system and a flatter valve operation characteristic (independent of the flow resistance on the receiver).

The flow regulators may be in an electrically controlled version, proportionally ensuring quick, smooth regulation of the flow rate.

We hope that the above article has broadened your knowledge about flow control valves and will help you choose the optimal solution tailored to your needs.

LET US BE IN TOUCH!

EXPORT DEPARTMENT

tel. +48 33 488 28 20-29

e-mail: export@ponar-wadowice.pl