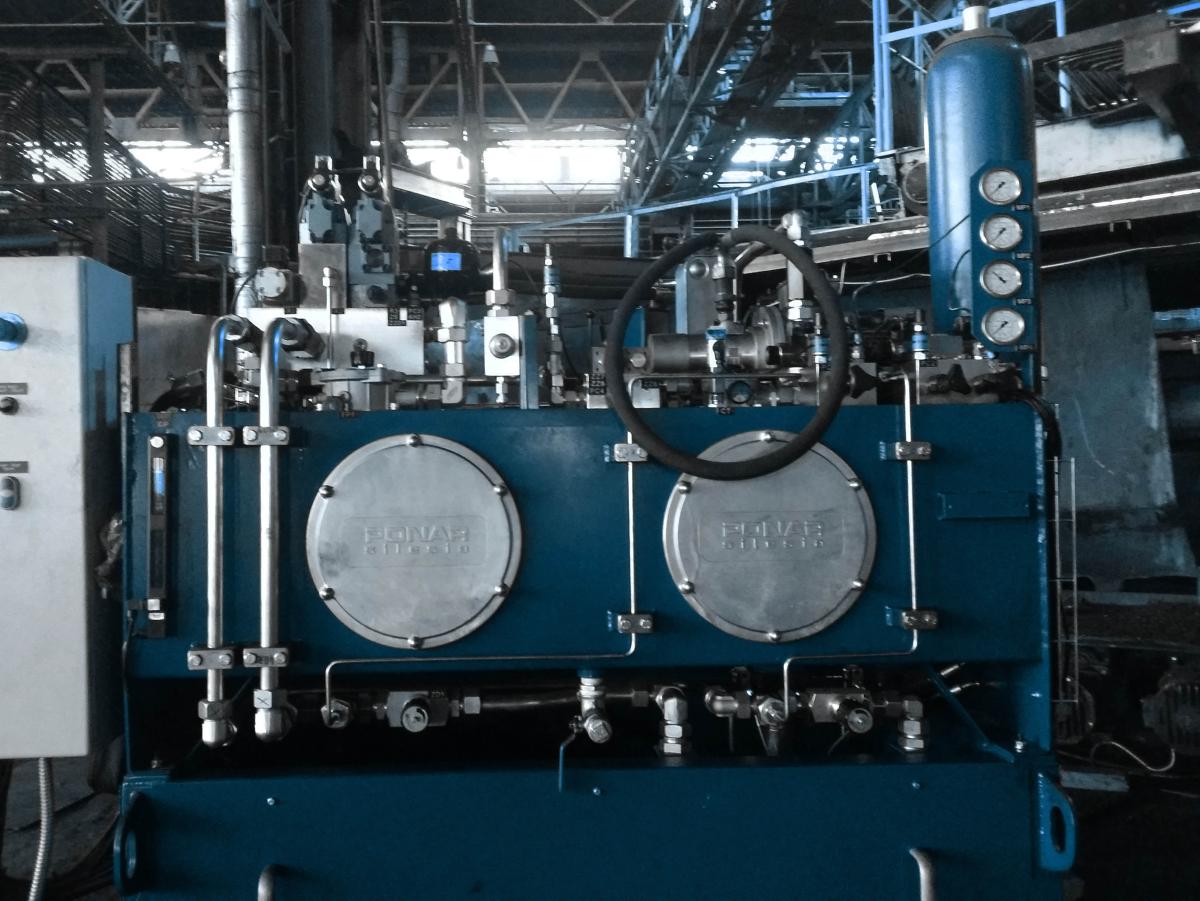

A system of billet thrower drive

PONAR Wadowice has modernized and manufactured a system of hydraulic drive of abillet thrower. The device is used for taking steel billets of 5-8 t. out of the furnace.

Before the upgrade, the device was equipped with a grab cylinder, apneumatic clamp and electric drive of acart. The moderni-sation was focused on manufacturing anew hydraulic power packs based on double piston pump, supplying the control system powering the system of receivers. After modernisation, the power pack is driven by: the grab cylinder with an in-built route transducer, clamp cylinder, cart motor, emergency system of cart leaving the furnace. The drive system, for achieving gentle motion is controlled by apro-portional directional control valve, manufactured by PONAR Wadowice. The accumulators on the power packs allows for completion of the work cycle in case of afailure of the electric power supply.

technical parameters of hydraulic system

| nominal capacity of the tank | 400 dm3 | supply voltage of electric motor |

3 x 400 V; 50 Hz | hydraulic fluid type |

olej mineralny |

| pump type |

tłoczkowa | electric motor power | 30 kW | optimal viscosity of the fluid |

46 mm2/s |

| section 1 pump capacity |

71 cm3/obr. | supply voltage of heaters |

3 x 400 V; 50 Hz | filtration | 6 µm |

| section 2 pump capacity | 45 cm3/obr. | supply voltage of control elements |

24 V - DC | optimal oil temperature range |

40÷55 °C |

| nominal working pressure of the pump unit 1 |

150 bar | electric motor typ of the B35 pump unit |

FCPA 90 L-2/HE | allowable oil temperature range | 20÷70 °C |

| nominal working pressure of the pump unit 2 |

200 bar | supply voltage of the cooler unit |

3 x 400 V; 50 Hz | ambient temperature range |

-15÷35 °C/50 °C |

| electric motor type of the pump unit |

VCMP200L-4 | electric motor power | 2,2 kW | max. noise level |

85 dB(A) |