research & development center

The Research and Development Centre of PONAR Wadowice deals with upgrading existing products and searching for new solutions within the area of hydraulic drives and controls.

Thanks to this, our offer keeps being expanded and existing or hydraulic components are replaced by new products, featuring new functional versions.

The Centre is responsible for carrying R&D works on oil hydraulic elements and complete hydraulic systems that feature innovation, optimised approach to machinery and equipment.

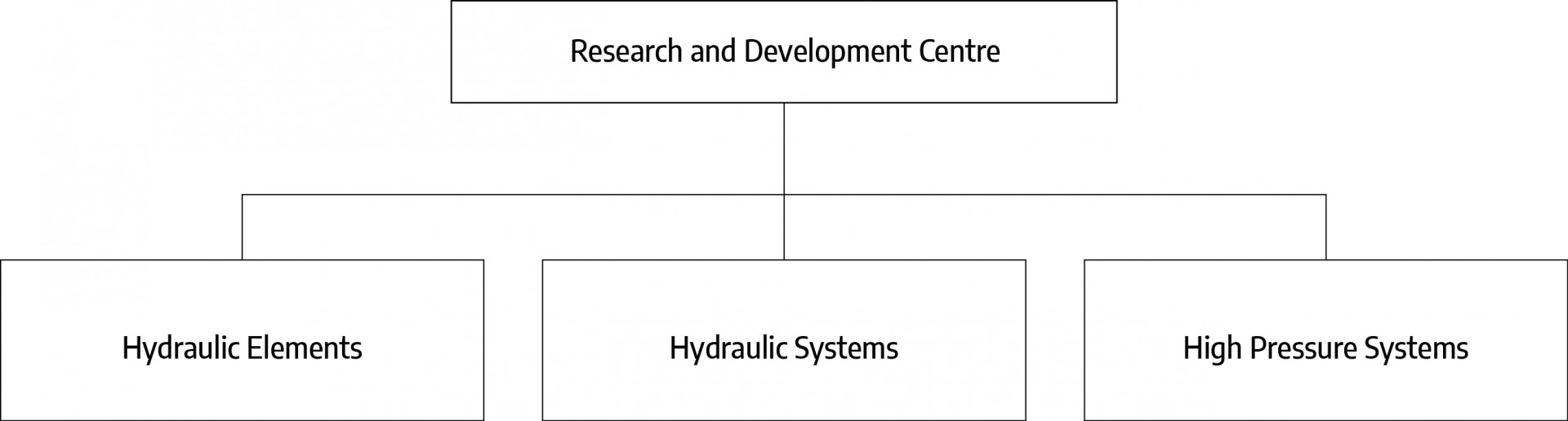

Structure of the R&D Centre:

The Centre consists of several departments located in each of PONAR Wadowice plants, dealing with oil hydraulic elements and systems:

Advanced technical resources, including:

Rapid development of our products and services is possible thanks to utilizing advanced technical resources, are facilities are equipped with:

- a hydraulic dynamometer with energy recovery for testing hydraulic drives and complete system of high power

- a cylinder test rig with an external load from the side of the piston

- a valve test rig

- a stand for development load sensing systems

- a stand for testing planetary gears with hydraulic drive

- an environmental chamber for testing valves

- a rig for simulation vibrations for testing valves intended for mobile machinery applications

- a stand for testing hydraulic pumps and motors

- an oil laboratory

The R&D Centre provides technical possibilities:

- allows for testing hydraulic cylinders with load up to 70 tons

- provides an opportunity to keep the constant mommentum from 0 to 3.000 obr/min.

- energy recovery -> decrease of power consumption use for research by 85%

- testing of planetary gears powered by a hydraulic motor under full load of 130 kNm

- testing of hydraulic motors under continuous load from the side of shaft, of power up to 175 kW

- long-time tests of pumps and systems under continuous load up to 200 kW

- tests and examination of valves under flow rate up to 700 l/min and pressure up to 400 bar

- tests and examination of hydraulic elements in extreme temperatures -70 / +800 C

- providing tests of resistance of hydraulic elements to vibration, up to 100 Hz

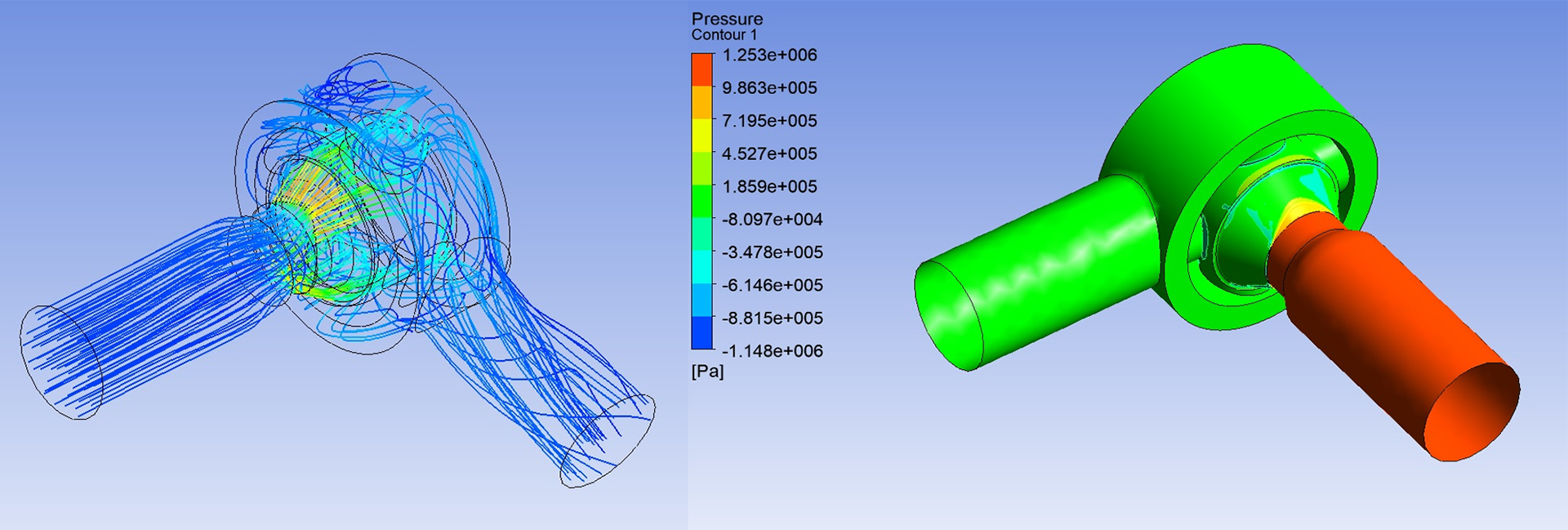

The Research and Development Centreis utilizes a calculation and simulation software: ANSYS/Fluent/CFX (for simulating flows), Matlab/SIMULINK, INVENTOR ULTIMATE (for performing durability calculations MES), ALTIUM DESIGN (for designing electronic circuits and PCB), Data Acquisition.

Research and Development in PONAR Wadowice:

- makes it possible to create similar load conditions, close to real working conditions of a hydraulic element or system

- allows for carrying out long-time tests

- energy saving during tests thanks to energy recovery

- reducing the amount of "experimental equipment" at Customer's site

- a possibility to reliably verify with the Customer assumptions or possible versions of the project in its early stage (preseed)

- a possibility of recording or "on-line" broadcasting of the recordings to Customers during system tests - remote participation of the Customer in the tests carried out in Łaziska Górne plant.

- completes the services offered by PONAR Wadowice by supplementing them with a whole spectrum of R&D services.

- optimising costs thanks to 100% tax relief for R&D projects.

- offering technology, knowledge, know-how and experience.