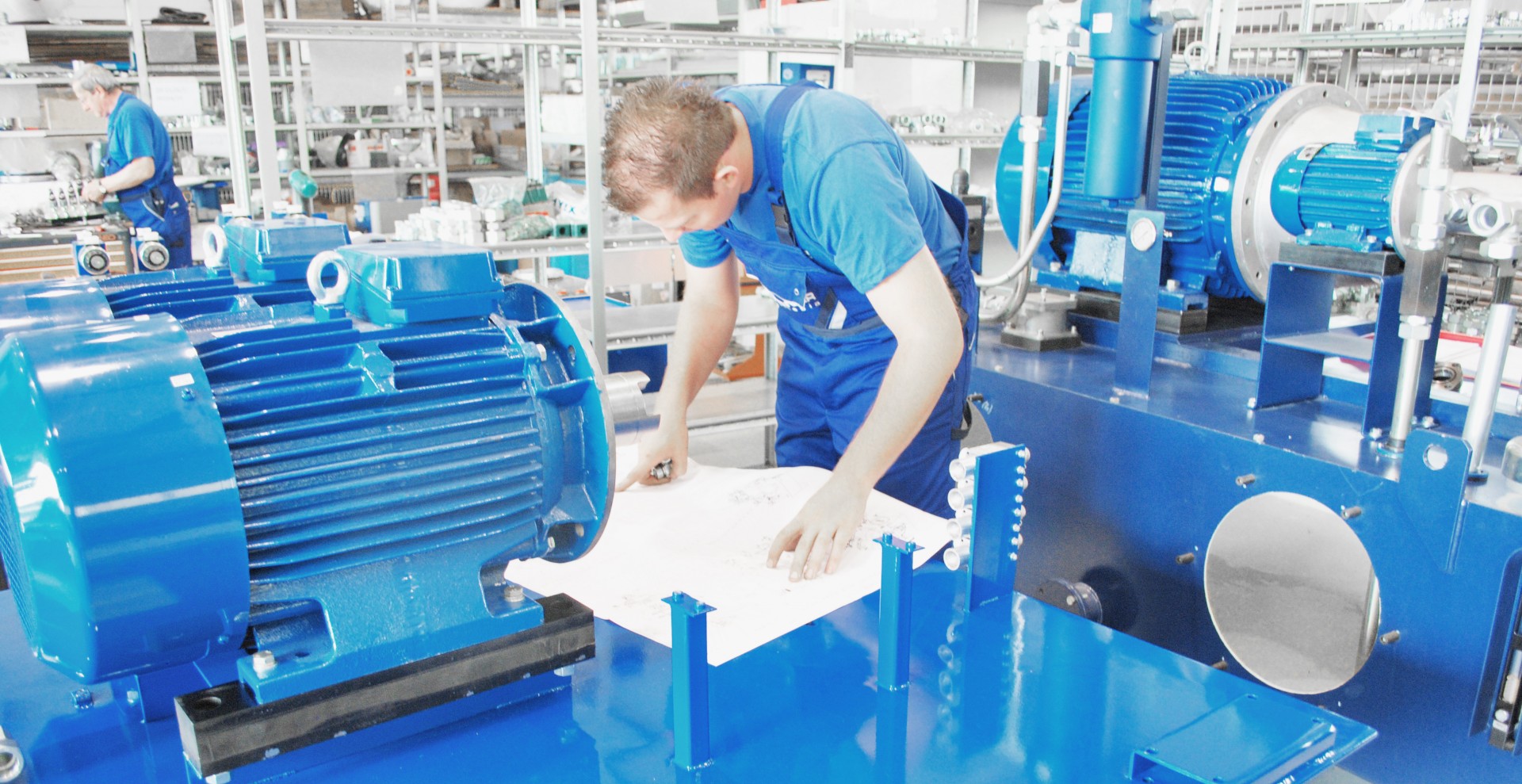

repair and diagnostics

The company offers a comprehensive range of services including regeneration of hydraulic elements of our own products as well as products of other manufacturers.

Only the parts and components of approved quality standards for mass-produced items are used in repairs and maintenance. When the task is completed, all the equipment is carefully inspected for compliance with the requirements for new products and is given a six months warranty

The scope of our service for diagnostics and modernization of hydraulic systems includes:

- technical operation and maintenance of hydraulic systems to ensure their long and reliable service

- modernization of old hydraulic systems and upgrading them to match the level of latest technical standards

Our own technical base

We own a high-class diagnostics equipment making possible to provide dynamics measurement and recording of the pressure, flow and oil cleanliness class.

The Company provides inspection and diagnostics of hydraulic accumulators regarding the wear, suitability for further operation, and UDT (Technical Inspection Office) acceptance. Our service unit carries out internal and external examination of pressure tanks, supported by magnafluxing, pressure tests and measuring the wall thickness, supervised by the UDT, TÜV, GL, ABS employees or other associations or organizations.

We also perform inspections of safety valves produced by our company or other manufacturers. The Customer is given full documentation necessary for UDT submission

Cleaning process advice and brokerage

PONAR Wadowice has extensive knowledge on performing cleaning of industrial installation, that is why we can help in selecting the right technology of cleaning:

- process automatisation

- increasing the speed of the process

- lowering the costs of cleaning

- safety of the operators

Our company carries out cleaning in cooperation with other companies providing such servises with utilising our equipment and knowledge.

Repairs and upgrades

As experienced engineering-servicing staff, PONAR Wadowice upon Customer's request porvides repairs and ongoing servicing of most of high pressure machinery and equipment used during UHP operations. Our professionalism and many years of experience guarantee long life of the equipment during performing commissioned works in the future.

We also carry out comprehensive upgrades of equipment, such as:

- change of technical parameters

- changes to existing functionalities

- change of external dimensions, etc.

Please feel welcome to contact us if the equipment that you own does not meet technical requirements and/or does not meet market expectations. Our Company provides support and offers solutions that will help you to modernise your equipment.