Modernization of mechanical drives on the Rzeszów Barrage

The PONAR Wadowice company participated in the project of modernization of mechanical drives at the Rzeszów Barrage.

The Rzeszów Barrage is located on the Wisłok River, its main task is to draw water directly from the reservoir used to produce electricity. The step also serves as a bridge, facilitating car communication.

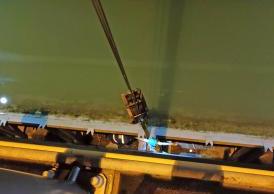

The barrage weir has four spans closed with gate valves equipped with movable ice flaps. Each gate valve flap is driven by a hydraulic cylinder, and for each hydraulic cylinder a power supply unit has been designed that allows for even lifting of the gate valves.

As part of the project, our company was responsible for the development, production and assembly of mechanical drives.

The modernization also included the delivery of automated hydraulic systems responsible for lifting the weir gate valves and ice flap cylinders.

We have designed hydraulic systems that allow for automatic operation and are equipped with a measuring system and appropriate overload protection.

Each hydraulic power pack consists of a tank made of carbon steel.

A valve block with 3 control sections is built on the power pack frame, each block consists of the folowing elements:

- WE-type valves responsible for controlling the direction of oil flow (direction of the cylinder movement)

- pressure-relief valves type UZPR limiting the maximum pressure in the system in a given pressure line

- controlled check valves type Z2S enabling free flow of oil in one direction and self-closing in the opposite direction, with the possibility of opening this flow with control pressure (protects cylinders against movement caused by external forces)

In addition, the system also includes:

- VRFU check/throttle valves for setting the flow rate in one direction and free flow in the opposite direction (setting the speed of the cylinder movement)

- cut-off valves type BK - blocking the flow of oil in a given line

system specifications

| nominal capacity of the tank |

400 dm3 | working medium type |

hydraulic oil 20÷400 mm2/s |

optimal viscosity of the fluid |

20-35 mm2/s |

| main pump type |

gear | nominal working pressure |

15 MPa | filtration | 10 µm |

| main pump capacity |

16 cm3/rev. | voltage of solenoid coil |

24 V - DC | ambient temperature |

- 15÷35 °C |

| electric motor power |

7,5 kW | max. noise level |

85 dB(A) | oil temperature |

40÷55 °C |

The supplied double-acting cylinders are equipped with an electronic measurement of the piston rod extension, which guarantees measurement with an accuracy of 1 mm. The piston rod and bearing eyes are made of stainless steel, and the cylinder itself is protected against corrosion with a special paint coating, and the gland and piston are double sealed.

Learn more about our other interesting solutions for all industries!

dane techniczne siłownika

| piston | 235 mm | stroke | 1400 mm |

LET US BE IN TOUCH!

SALES DEPARTMENT - hydraulic systems

tel. +48 32 323 34 00 | e-mail: systemy@ponar-wadowice.pl