Pressure tests rig

Our Company is engaged in production of both: oil hydraulic power pack and specialised test rigs.

Our solutions are designed in cooperation with the Customer, in accordance with the requirements and adapted to the needs of the investment.

The designed stand is intended for carrying out pressure and tightness tests of pipes.

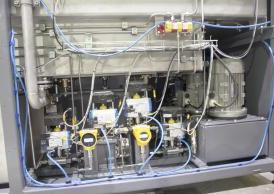

The test stand consists of: a test chamber, an oil hydraulic system, a water system, a pneumatic system and an electrical control system.

The task of oil system is opening and closing of the test chamber by means of hydraulic cylinders and supplying oil under correct pressure for multiplicator chambers.

The pressure on the multiplicator is regulated using a proportional valve

The pressure on the oil pumps is limited by pressure-relief valves UZPD6 i UZPS6.

The water system is used to supply test connections with water at the required pressure. The pump unit initially fills the multiplier and the tested element, and then the pressure is increased using the multiplier. Two-way valves with pneumatic drive allow for powering the appropriate connections in the test chamber and switching on the measurement systems.

The tested elements are connected to quick connectors on water collectors.

Water is also used to fill the test chamber tank, where leak tests of elements are carried out using compressed air.

A movable platform is installed in the tank on which the tested assemblies are placed to be immersed in water.

The moving platform is raised and lowered using an electric screw lift.

The water in the station is filtered and sterilized with a UV lamp.

The pneumatic system is designed to supply the test connections with air at the appropriate pressure and maintain the control pressure required for pneumatically controlled valves.

The compressed air collector is immersed in water together with the tested element.

Oil and water tanks are equipped with electric minimum liquid level switches that protect against dry running of the pumps.

technical data

| nominal capacity of oil tank |

60 dm3 | max. pressure of oil in the oil system | 300 bar | hydraulic fluid in the oil system |

mineral oil |

| nominal capacity of water tank |

436 dm3 | max. pressure of water wody in the test system |

630 bar | working medium in the test system | demineralised water |

| control elements supply voltage |

24 V DC | max. pressure of air in the pneumatic system pneumatycznym | 6 bar | max. noise level |

85 dB(A) |

| optimal range of oil temperature |

40÷55 °C | allowable range of oil temperature |

20÷70 °C | allowable range of water temperature |

10÷30 °C |

See our other interesting applications for each major industry.

LET US BE IN TOUCH!

SALES DEPARTMENT - hydraulic systems

tel. +48 32 323 34 00 | e-mail: systemy@ponar-wadowice.pl