We have been building trust for over 55 years!

The highest quality of products has always been our priority, which has been repeatedly confirmed by numerous certificates. However, it is the trust that our clients and partners place in us that is our highest distinction.

Comprehensive inspections of prcesses at every stage of production.

The quality control process begins with checking the materials and components used in production. Another element is the collection of details and finished products. This process can be divided into three stages:

- first item control, including full measurement of prototypes - after the end of a given production stage

- departmental control - checking between individual stages of the technological process

- final control - at the end of the technological process.

Then the functionality of a finished product is tested and the quality documentation is completed - declarations, approvals, certificates, certificates, measurement cards, reports on the process of applying paint coatings or other documents required by the customer (e.g. FAI, FMEA, process cards, MSA, process capability analysis Cpk).

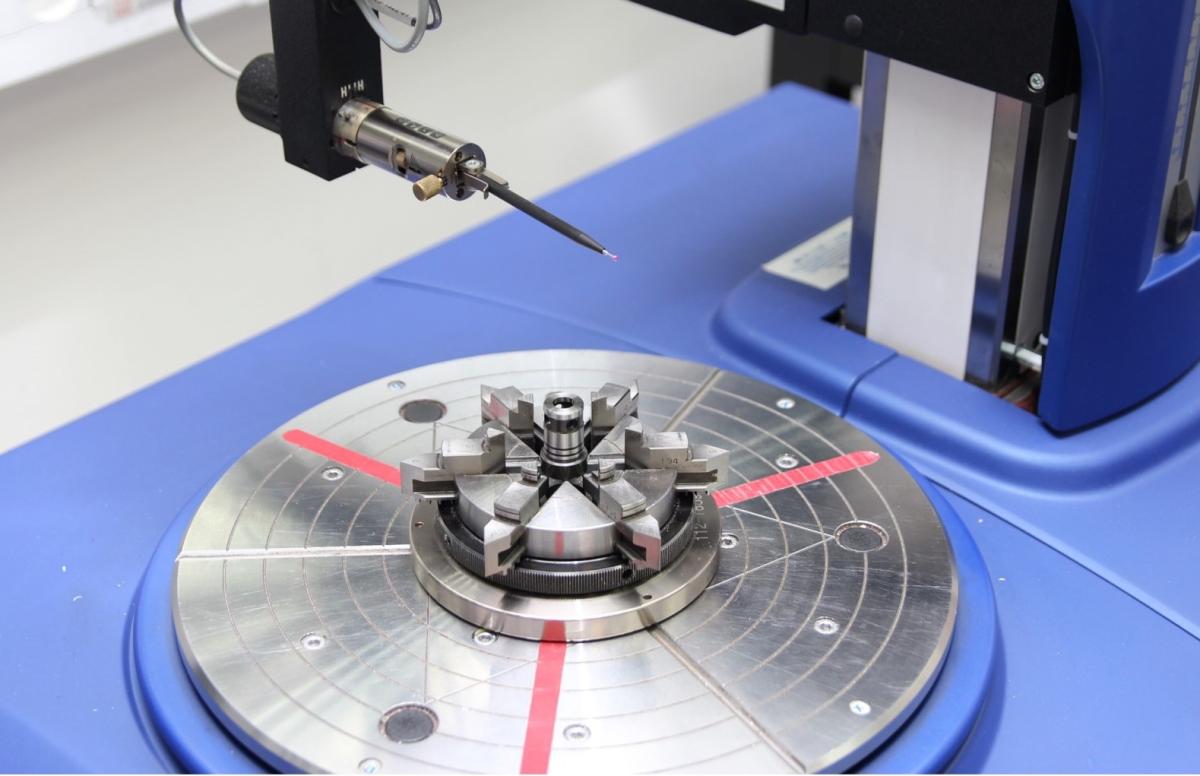

Cutting-edge laboratory equipment.

Our laboratories are equipped with modern measuring devices and specialized equipment for carrying out control and measurement tests. We have, among others:

- coordinate machines ALTERA S 10.7.6 by LK Metrology and Zeiss Eclipse - for precise 3D measurements

- Talyrond 565 / 585H laboratory device for measuring both shape error parameters (such as roundness or cylindricity), roughness, waviness and contour measurements

- roughness and contour measuring device - Form Talysurf Intra

- Qness Q10 M micro hardness tester for measuring the depth of carburized, nitrided, carbonitrided, nitrocarburized layers and for measuring the

- hardness using the Vickers EN ISO 6507, Brinell EN ISO 6506 and Knoop ISO 4545 methods

- universal optical machine type MarShaft SCOPE 250 plus for measuring small axisymmetric parts, e.g. turned parts

- STH 21 test stand for functional testing of finished products

- hydraulic testers type PPC-08 for accurate measurement of flow and pressure.

Certificates, approvals, standards.

We have the ISO 9001: 2015 Quality Management System Certificate, ISO 14001: 2015 Environmental Management System Certificate, certificates for intrinsically safe products (ATEX), certificates for special production: AQAP, NCAGE, MSWiA license. Our products also have the required documents for compliance with the Pressure and Transport Directive, allowing them to be used in many industries. We make products in accordance with the requirements of DNV.

All certificates can be downloaded at https://www.ponar-wadowice.pl/certifikaty.

It is thanks to the well-equipped technical facilities, experienced employees and our own research and development departments that we are able to offer the highest quality products that meet the needs of even the most demanding customers.